|

This process improves wool and woollen-mix

materials especially with regard to texture structuring and the appearance of the product. During this process either steam not under pressure and in a cooled-down state is brought into contact with the

material or controlled humidity is introduced into the treating area and over the material and is then converted into steam by pressure and the effect of heat. This process improves wool and woollen-mix

materials especially with regard to texture structuring and the appearance of the product. During this process either steam not under pressure and in a cooled-down state is brought into contact with the

material or controlled humidity is introduced into the treating area and over the material and is then converted into steam by pressure and the effect of heat.

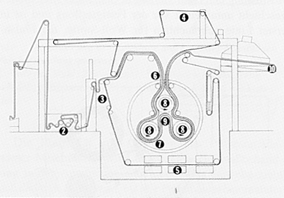

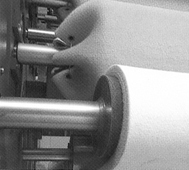

In the continuous decatizing process needle felts or silicone blankets are used. Furthermore, to protect the needle felts underwindings and fleeces are employed. Hocks can supply you with all these materials from a single source. In the continuous decatizing process needle felts or silicone blankets are used. Furthermore, to protect the needle felts underwindings and fleeces are employed. Hocks can supply you with all these materials from a single source.

NEEDLE FELTS:

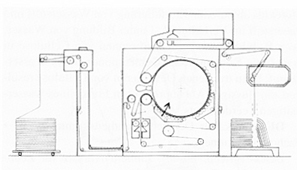

The calendering machines for continuous decatizing of fabrics and knitted materials are usually equipped with

endless needle felting. The felts on offer from Hocks have been especially developed in order to guarantee faultless operation on the continuous decatizing machine through a

high degree of stability and strength. The surfaces of our felts are very smooth in order to rule out marking on the fabrics or knitted material. Only special polyester fibres,

which are accordingly hydrolysis-resistant, are used to avoid destruction of the blanket under extreme temperature and moisture conditions. The calendering machines for continuous decatizing of fabrics and knitted materials are usually equipped with

endless needle felting. The felts on offer from Hocks have been especially developed in order to guarantee faultless operation on the continuous decatizing machine through a

high degree of stability and strength. The surfaces of our felts are very smooth in order to rule out marking on the fabrics or knitted material. Only special polyester fibres,

which are accordingly hydrolysis-resistant, are used to avoid destruction of the blanket under extreme temperature and moisture conditions.

Hocks can supply both the endless decatizing felts and the Machon including non-rusting eyes and cord. Hocks can supply both the endless decatizing felts and the Machon including non-rusting eyes and cord.

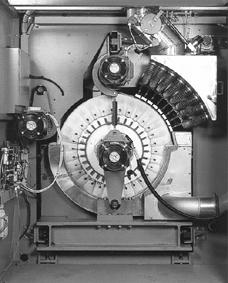

SILICONE BLANKETS SILICONE BLANKETS

Thanks to endless belt production our silicone blankets have a significantly longer life than similar products to be found on the market.Due to the absence of

overlapping connecting pieces the endless composition makes a finish without marking possible. The hand-ground, rub-resistant surface is a guarantee for a long-lasting, optimal decatizing quality.

UNDERWINDINGS

We offer polyester underwindings as well as Aramid

underwindings with hand-combed ends.

At the customers request the reverse side of the winding can be strengthened.

FLEECE

As a protection and to extend the life of the Machons on the decatizing machinery we offer a very uniform light fleece weighing approximately 30gr. per square metre. This is

wound around the Machon in several layers and should be continually changed.

These materials can be used on the decatizing machinery of the following firms (amongst

others): Biella Schrunk, Bisio, Fité, Hemmer, Marther, Menschner, m-tec, Sperotto Rimar etc.

Please contact us well be pleased to give advice.

|